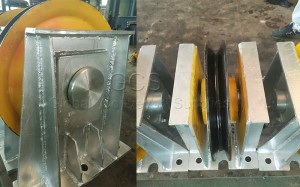

Theha foreimi ea Wheel ea Tšepe ea Haulage Pulleys

V-Belt Casting Pulleys

Re ba bang ba bahlahisi ba ka sehloohong le barekisi ba mefuta e mengata e fapaneng ea Cast Iron Pulleys.Li-pulleys tsena li etsoa ka thepa e tala ea boemo bo holimo, e rekoang ho tsoa ho barekisi ba tšepahalang ba 'maraka.Ho feta moo, re fana ka li-pulleys tsena likarolong tse fapaneng tse kang a, b, le c.Tse latelang ke litlhaloso tse fapaneng tsa sehlahisoa se fanoang ke rona

Cast Iron V-belt pulley "a" karolo [ho tloha ho 1 groove ho ea ho 5 grooves]

Motsoako o boima oa samente oa liindasteri o lahlang groove pulley e habeli

Steel Rope Sheave Pulley ke mofuta oa sesebelisoa sa bohlokoa sa ho phahamisa, se bonolo ka sebopeho, se bonolo ho se sebelisa.E ka fetoha

tataiso ea khoheli ea pulley le sehlopha sa pulley, e ka boela ea phahamisa le ho tsamaisa ntho e boima, haholo-holo

sehlopha sa pulley, hammoho le winch, mast, le mochini o mong oa ho phahamisa, o sebelisoang haholo kahong.Tlhaloso

ea lethathamo la lihlahisoa ho tloha 0.03t-320t.

Steel Rope Sheave Pulley e sebelisoa haholo ho Crane Manufacturer, Bolaoli ba boema-kepe, Sekepe, Hoist, Crane ea Truck, mechini e meholo ea kaho,

Indasteri joalo-joalo.Theko ke ea referense feela, ka kopo ikopanye le rona haeba o na le tlhoko.

| Lebitso la sehlahisoa | mabili a pulley | ||

| Lintho tse bonahalang | 45 #, Q235B, Q235A, Q345A, Q345B, tšepe ea alloy, tšepe ea carbon, joalo-joalo (Joalo ka kopo ea moreki) | ||

| Ho sebetsa | Lathing, ho sila, ho sila, ho phunya | ||

| Phekolo ea mocheso | Normalizing, annealing, botsofali, thatafatsa, le tempering | ||

| Max.diameter | 5000mm | ||

| Bolelele | 8000 limilimithara | ||

| Max.mamello | ±0.2 | ||

| Max.boima | 10T | ||

| Mofuta | Ho latela litšoantšo | ||

| Tlhahlobo | tlhahlobo ea boholo, tlhahlobo ea tikoloho ea kantle, tlhahlobo ea pono, tlhahlobo e kenang, tlhahlobo e felileng ea sehlahisoa, ho lemoha liphoso | ||

| Nako ea thomello | Matsatsi a 30-90 | ||

Theha foreimi ea Wheel ea Tšepe ea Haulage Pulleys

Video ea Cast Aron Wheel bakeng sa Haulage Pulleys

GCS e na le tokelo ea ho fetola boholo le data ea bohlokoa ka nako efe kapa efe ntle le tsebiso.Bareki ba tlameha ho etsa bonnete ba hore ba fumana litšoantšo tse netefalitsoeng ho tsoa ho GCS pele ba phethela lintlha tsa moralo.

Khetho ea conveyorrolara

Conveyor rolarae sebelisetsoa ho tšehetsa lebanta la conveyor le lisebelisoa tse holim'a lebanta, ho fokotsa ho hanyetsa ho sebetsa ha lebanta la conveyor, ho etsa bonnete ba hore sag ea lebanta la conveyor ha e fete melao ea theknoloji, 'me e etsa hore lebanta la conveyor le sebetse hantle ka tsela e reriloeng esale pele.

Roller ho latela ts'ebeliso ea eona e arotsoe haholo-holo ka carrier roller, return roller, impact roller le align roller.Roller ke e 'ngoe ea likarolo tsa bohlokoa tse amang ts'ebetso ea conveyor, e ikarabellang bakeng sa 30% ~ 40% ea boleng ba conveyor kaofela, 25% ~ 30% ea theko ea conveyor kaofela,' me ke karolo ea mantlha ea letsatsi le letsatsi. tsamaiso, tshireletso le ho nkela sebaka.Ho hlophisa le ho khethoa ha rolara ho na le tšusumetso ea bohlokoa ts'ebetsong e tloaelehileng ea conveyor, mosebetsi o tsitsitseng, tšebeliso ea matla le theko ea conveyor eohle.Haholo-holo tabeng ea lebelo le phahameng la lebanta, litlhoko tsa rolara li ntse li e-ba thata haholoanyane.

E le karolo e ka sehloohong ea conveyor, rolara e se e le thata le ho feta ka tsoelo-pele ea lebelo la lebanta.Lintlha tse ka sehloohong tse amang ts'ebetso ea lebelo le phahameng la rolara ke boleng ba ho tsoa le boleng ba ho hanyetsa ho potoloha.Ha rolara e sebetsa ka lebelo le phahameng, mohaho oa ho tiisa oa rolara o tla angoa ke mocheso le mabaka a mang.Moralo oa moralo oa lirolara tse lebelo le holimo o hlahisitsoe pampiring ena.

1.SEaling sebopeho saroller

Sebopeho sa ho tiisa ke ntlha ea bohlokoa e amang bophelo ba ts'ebetso le ho hanyetsa ho sebetsa ha rolara.Ho na le mekhoa e 'meli ea mantlha ea sebopeho sa tiiso ea li-roller 'marakeng:

(1) Non-touch seal (joaloka labyrinth seal).Ho hanyetsa ho sebetsa ha mofuta ona oa ho tiisa ho nyane, empa ka lebaka la ho ba teng ha likhohlano tsa ka hare ha ho sebetsa ka lebelo le phahameng, ho tla lebisa ho etsahala ha mocheso.Ka phetoho ea khatello ea moea, likaroloana tsa lerōle li kena ka har'a sekoahelo sa tiiso hammoho le ts'ebetso ea ho inhalation, e leng se etsang hore ho be le ho sebetsa boemong ba ho kena-kenana le likhohlano, le ho mpefatsa ho roala ha bere.

(2) Tšoaea mofuta oa tiiso.Phello ea ho tiisa e molemo ho feta mofuta o sa amaneng, empa khanyetso ea ho sebetsa e kholo.Tabeng ea phapang e kholo ea mocheso le khatello le kabo e sa tsitsang, deformation ea elastic ea molomo oa ho tiisa le eona ha e lumellane, e fella ka phello e mpe ea ho tiisa.

Ha se ntho e ntle ho eketsa phello ea ho tiisa feela ka ho eketsa palo ea litsela tsa ho tiisa le bolelele ba ho tiisa.Sebopeho sa ho tiisa labyrinth sa lekhalo la pele la ho potoloha ke senotlolo sa ho sebetsana le bothata ba ho tiisa, mathata a lekhalo, slime kapa metsi a tla phalla ka har'a mocha o ka hare oa labyrinth, ho baka ho hlōleha ha rolara, palo e joalo ea maze ha e na moelelo.

Rola e hlahisitsoeng pampiring ena e nka sebopeho se kopaneng sa axial labyrinth seal le touch seal, 'me litšobotsi tsa eona ke tse latelang:

(1) Palo ea likarolo tsa ho tiisa ha axial labyrinth seal ha e amehe ke tekanyo ea radial ea ho beha, 'me e ka eketsoa ka mokhoa o nepahetseng.Sebaka sa ho tiisa sa axial labyrinth se tseleng e ts'oanang le matla a centrifugal a phallo ea metsi.Metsi a keneng ka

tiiso ha rolara e potoloha e tla phalla holimo ho labyrinth hammoho le holim'a ho tiisa tlas'a phello ea matla a centrifugal.E le ho ntlafatsa phello, holimo ho lesale la ho tiisa ka hare ho ka nkoa e le ho khetha sebopeho sa selikalikoe sa arc.

(2) Eketsa lesale la ho tiisa ka lehlakoreng le ka ntle la labyrinth seal ho etsa tiiso ea ho ama, e ke keng ea sebetsana le "bothata ba phefumoloho" ea tiiso ea labyrinth, empa hape e ke ke ea eketsa botebo ba setulo sa ho jara joaloka meaho e meng e kopantsoeng ea tiiso.Thepa ea ho tiisa ea NBR/PA6, boima bo bobebe, khanyetso ea kutu, coefficient ea likhohlano e nyane ho feta lipolasetiki tse ling tsa boenjiniere.

(3) eketsa lesale la convex holim'a selikalikoe sa ka hare (sheba Setšoantšo sa 1), fetola tsela ea ho tsamaea ha axial ha lerōle kapa metsi a kena ka lekhalo la lesale la ka hare la baffle.Ha rolara e sebetsa ka lebelo le phahameng, ho tla ba le vacuum pakeng tsa selikalikoe sa convex le selikalikoe sa kantle ho netefatsa hore ho tiisa tšebetso ea ho tiisa.

Litšobotsi tsa 2.Ts'ebetso le khetho ea thepa

The radial run out of the roller haholo-holo e itšetlehile ka phoso ea radial ea cylinder, boleng ba setulo sa ho jara le coaxiality ea ts'ebetso ea kopano.Boleng ba mahlaseli a marang-rang a rolara bo na le tšusumetso e kholo mosebetsing o boreleli oa conveyor, haholo-holo ha boleng ba mahlaseli a marang-rang bo le boholo haholo ka lebelo le phahameng, lebanta la conveyor le tla pota-pota ka matla le ho ama mosebetsi o tloaelehileng.

Hona joale, boholo ba li-roller tsa li-roller li nkeloa sebaka ke liphaephe tsa tšepe, tse boima ka boleng.Boleng ba liphaephe, ovality le ka ntle bophara tolerances ha ho bonolo ho tiisa, haholo-holo ho ba teng ha discontinuity ya moqomo sebopeho ama coaxiality, 'me ho ke ke ho le bonolo ho etsa hore rollers ba eccentric.Ho sisinyeha ha nako le nako ho tla etsahala ka lebaka la matla a centrifugal nakong ea ts'ebetso ea ho sebetsa, e tla ama ts'ebetso e bonolo ea lebanta la conveyor.

3. Khetho ea lirolara

Bophelo ba ho sebetsa ba rolara haholo-holo bo itšetlehile ka ho beha le ho tiisa.Batho ba bangata ba sa sebetseng 'marakeng ba sebelisa li-bearings tse kholo.Ha ho bapisoa le li-bearings tse tloaelehileng, li-bearings tse kholo li na le tumello e kholoanyane le li-diameter tsa bolo, tse ka fokotsang kutloisiso ho coaxiality le ho ntlafatsa bokhoni ba ho ikamahanya le lintho tse tsoang linaheng tse ling.

Leha ho le joalo, khetho ea li-bearings tse nang le tumello e kholo e tla ama haholo matla a axial bearing ea motho ea sa sebetseng, haholo-holo ka mor'a hore lebelo la lebanta le eketsehe, ho tsamaea ha matla a axial ho tla etsa hore boemo bo sa tsitsang ba ho sebetsa ba lebanta le tsamaisane.Esita le linakong tse boima, hoa hlokahala ho emisa mochine bakeng sa ho senya le ho fetola ho tloha qalong.

Ka pampiri ena, re rerile ho khetha li-bearings tse tebileng tsa bolo ea li-groove tse nang le sekoahelo sa lerōle, tse ke keng tsa tiisa feela bohloeki ba ka hare ho bering, ho ntlafatsa matla a ho bea axial , ho fokotsa tšenyo e atisang ho bakoa ke axial high-frequency. matla a tšusumetso, empa hape etsa bonnete ba hore ts'ebetso e boreleli ea bere e eketsa bophelo ba sebele ba ho sebetsa.

Pampiri ena e entse lipatlisiso tsa motheo ka li-rollers tse lebelo le phahameng ho tloha likarolong tsa sebopeho, ho tiisa, ho sebelisoa le theknoloji ea thepa e ncha.Rola e nka sebopeho sa ho tiisa se kopantsoeng se kopanyang labyrinth ea axial le touch labyrinth, 'me e sebelisa bolo e tebileng ea groove e nang le sekoaelo sa lerōle.Tšebeliso ea lisebelisoa tse ncha le phetoho ea theknoloji ea ts'ebetso e netefatsa ho hanyetsa ho potoloha ha rolara, ho qhomela ka selikalikoe sa radial le ho thibela metsi, ho tiisa lerōle le mesebetsi e meng.Tlas'a tataiso ea nts'etsopele ea li-conveyors tse nang le matla a phahameng, a nako e telele le a maholo, mohaho oa li-roller o hlahisitsoeng pampiring ena o na le khanyetso e nyenyane ea ho potoloha, lerata le tlaase le bophelo bo bolelele ba ts'ebetso, e leng se phethang karolo ea bohlokoa ho matla a phallo ea motlakase oa lebelo.

Global Conveyor Supplies Company Limited -Lirolara tsa letoto la RS

Shaft:Roller shaft e entsoe ka tšepe e pota-potileng e batang haholo, e sa kang ea halefa le ho halefa.Mochini oa ho sila ka mokhoa o nepahetseng, mochini oa clamping ring grooving o sebelisetsoa ho sebetsana le shaft, e le ho etsa bonnete ba hore phallo ea axial ea rolara e batla e le zero.

Tube:Roller shaft e entsoe ka tšepe e pota-potileng e batang haholo, e sa kang ea halefa le ho halefa.Roller shell e amohela phala e khethehileng ea tjheseletsa, tekanyo e nyenyane ea ho khumama, elasticity e nyenyane.Amohela seha se tsoetseng pele sa phala ea tšepe le sesebelisoa sa mochini oa lesoba le kahare, mochini o nepahetseng lipheletsong tse peli tsa phala ea tšepe, o netefatsa ka nepo hore o na le rolara, o fokotsa phoso ea machining.

Bearing:Ho roala rolara ho nka bolo e khethehileng ea C3 deep groove.Pele ho kopano, rolara e tlatsitsoe ka oli ea lithium 'me e tiisitsoe ka ho sa feleng mahlakoreng ka bobeli, e ka hlokomelang mahala ea bophelo bohle le ho lelefatsa bophelo ba ts'ebeletso.

Kopano ea tiiso:Karolo ea li-roller seal e entsoe ka thepa ea nylon, 'me sebopeho sa sebopeho ke sebopeho sa tiiso ea labyrinth.Ho tiisa ka hare le ka ntle ho theha mocha o phahameng oa labyrinth, mocha o tlatsitsoeng ka oli ea lithium ea nako e telele, e le hore rolara e be le ts'ebetso e ntle ea metsi le lerōle.Mochini oa ho sila ka mokhoa o nepahetseng, mochini oa clamping ring grooving o sebelisetsoa ho sebetsana le shaft, e le ho etsa bonnete ba hore phallo ea axial ea rolara e batla e le zero.

Bearing housing:Tlhahiso ea matlo a nang le thepa e amohela mokhoa oa ho etsa litempe tse nang le mekhahlelo e mengata ho netefatsa boemo bo nepahetseng ba ho beha le ho tiisa.Li-roller tubes le li-bearing housing lipheletsong tse peli tsa 3mm tse tletseng litšepe li tšehelitsoe ke tšireletso ea khase ea carbon dioxide ka nako e le 'ngoe le mochine o nang le lithunya tse peli ho fana ka bonyane ba 70% ho kenella le ho etsa bonnete ba hore idling e lula e le matla le tlas'a meroalo e phahameng le lebelo le phahameng.

1. RS series rollers ke tsa GCS high-endho tsamaisa dirolara.

2. Rolara ea ho khutlisa / e tsamaisang / e nang le sekoti e na le mohaho o nepahetseng o phahameng o nang le likarolo tse ka bang robong tsa ho tiisa, ho netefatsa hore metsi le lerōle li thibela metsi.Ka litiiso tsa rabara kapa tsa tšepe, li-multi-groove labyrinth seals.

3. The bearing housing le rolara tube li welded ka ho feletseng ho etsa bonnete ba hore ho kopana hantle ho pholletsa le rolara.Setlolo ke setlolo sa kamehla.

4. Ho ea ka litlhoko tsa bareki, bokaholimo ba rolara bo ka penta ka 'mala ofe kapa ofe.

5. Boitsebiso: Hangata Q235 carbon steel (e nehetsoeng ho tsamaisa rolara), A3 e batang ea ho taka shaft (e ka ba ho nepahala ho phahameng ho latela litlhoko tse fapaneng tsa bareki).

6. Rolara e 'ngoe le e 'ngoe e tla feta tlhahlobo le tlhahlobo e tiileng ho netefatsa hore sehlopha ka seng sa rolara ke boleng bo holimo e le kannete.

Ka kopo ikutloe u lokolohile ho ikopanya le rona ho fumana lirolara tsa conveyor.

Re litsebi, theknoloji e babatsehang le tšebeletso.Re tseba ho etsa hore meqolo ea rona ea lipalangoang e tsamaise khoebo ea hau!Sheba hapewww.gcsconveyor.com Emailgcs@gcsconveyoer.com

Linyeoe tse Atlehileng